At Micro Manufacturing a lot of our design work comes from individuals and business that have an idea but don’t know how to turn it into a reality. we work closely with them in design what they’ve always wanted to make but couldn’t. we take great pride in being able to give our customers their creation no matter how big or small.

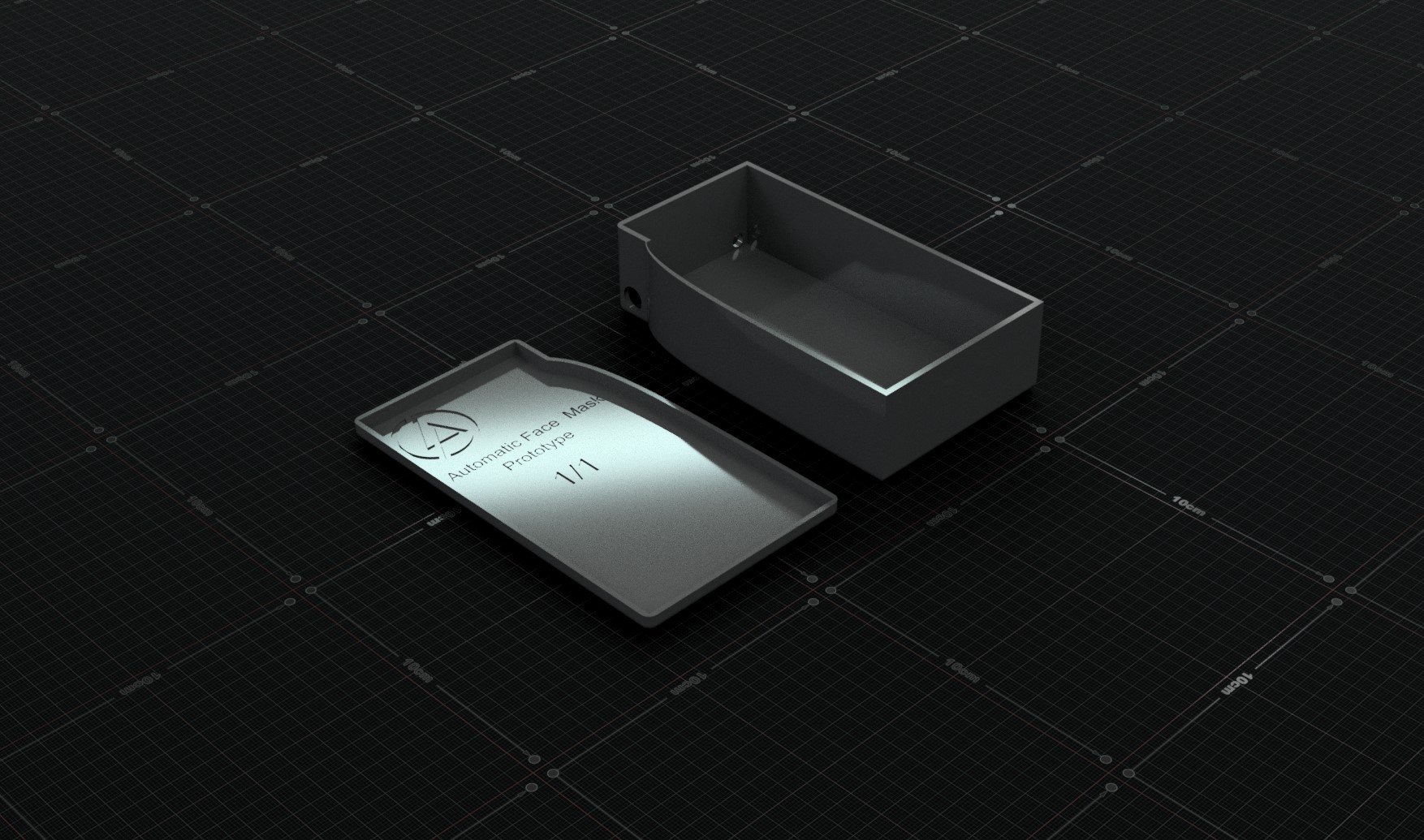

We specialize in 3D modeling and low-quantity production to bring your unique ideas to life. Whether it's a single prototype or a limited run, no job is too small for us. We are dedicated to delivering high-quality, precise models that meet your exact specifications, ensuring your vision becomes a tangible reality.

Repairing

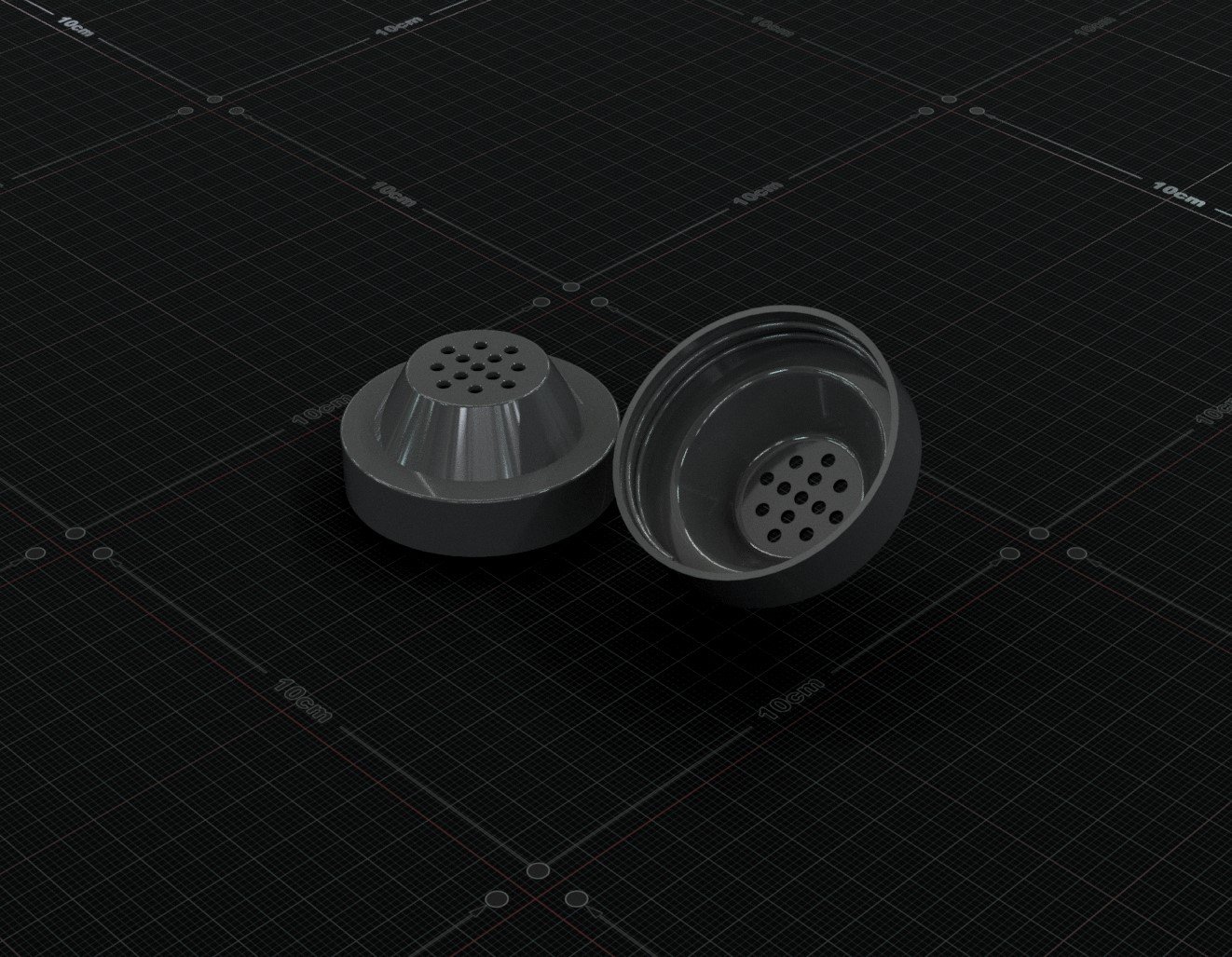

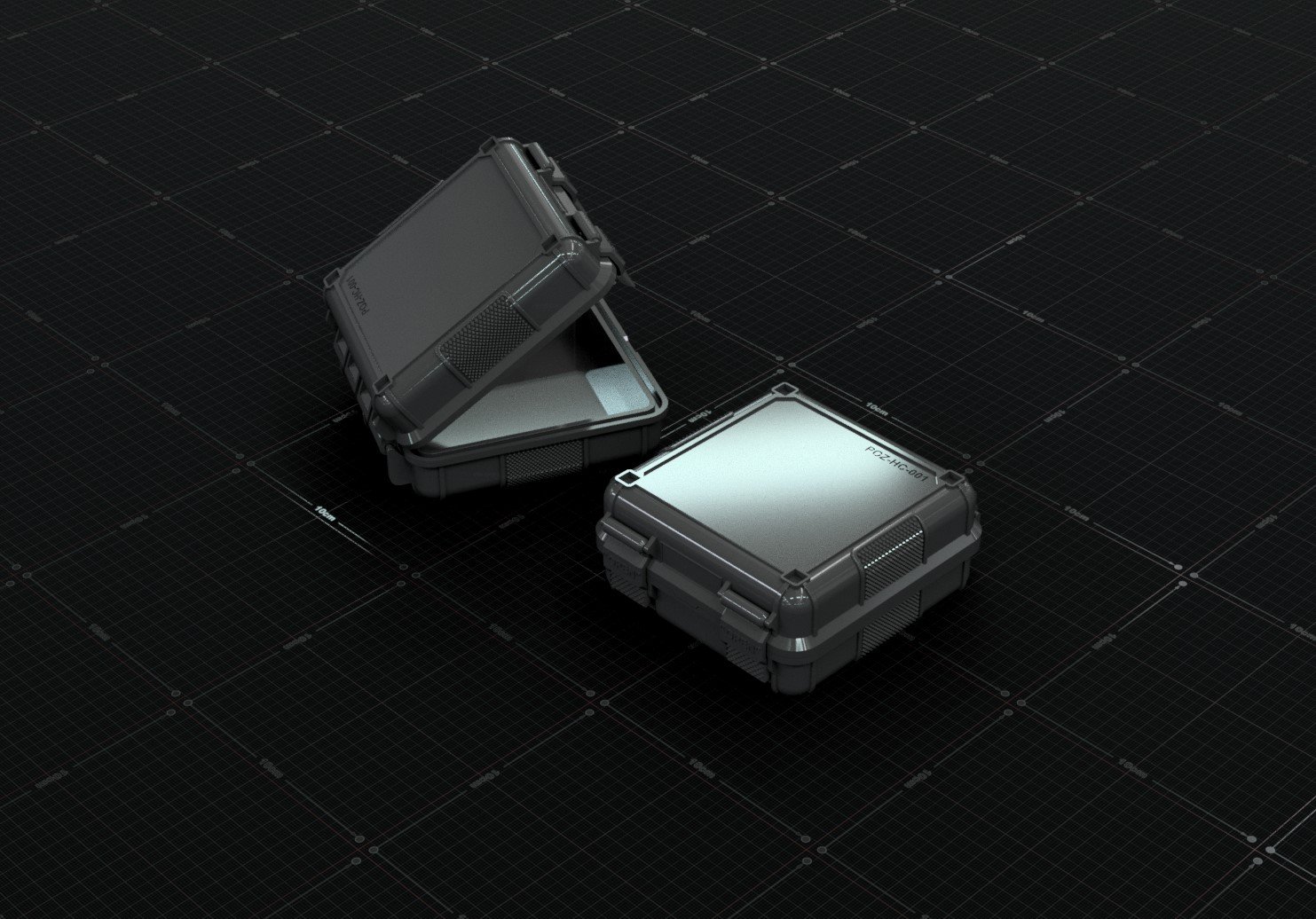

3D modeling opens up a world of possibilities. Not only can you immortalize your favorite items, but you can also breathe new life into old, worn-out possessions. For example, consider a set of salt and pepper shakers with broken lids—thanks to 3D modeling and printing, we can restore them, saving them from the landfill and allowing them to be used once again. This innovative technology makes it easier to repair, customize, and preserve items, giving them a second chance.

Before

Not only can your old items be restored and reused, but with 3D modeling, you now have a digital archive of your creations. This allows you to continuously reproduce your items as needed, potentially solving larger-scale problems that others may be facing, such as product shortages or the difficulty of replacing discontinued parts. The possibilities for sustainable, on-demand production are now at your fingertips.

After

Renewing

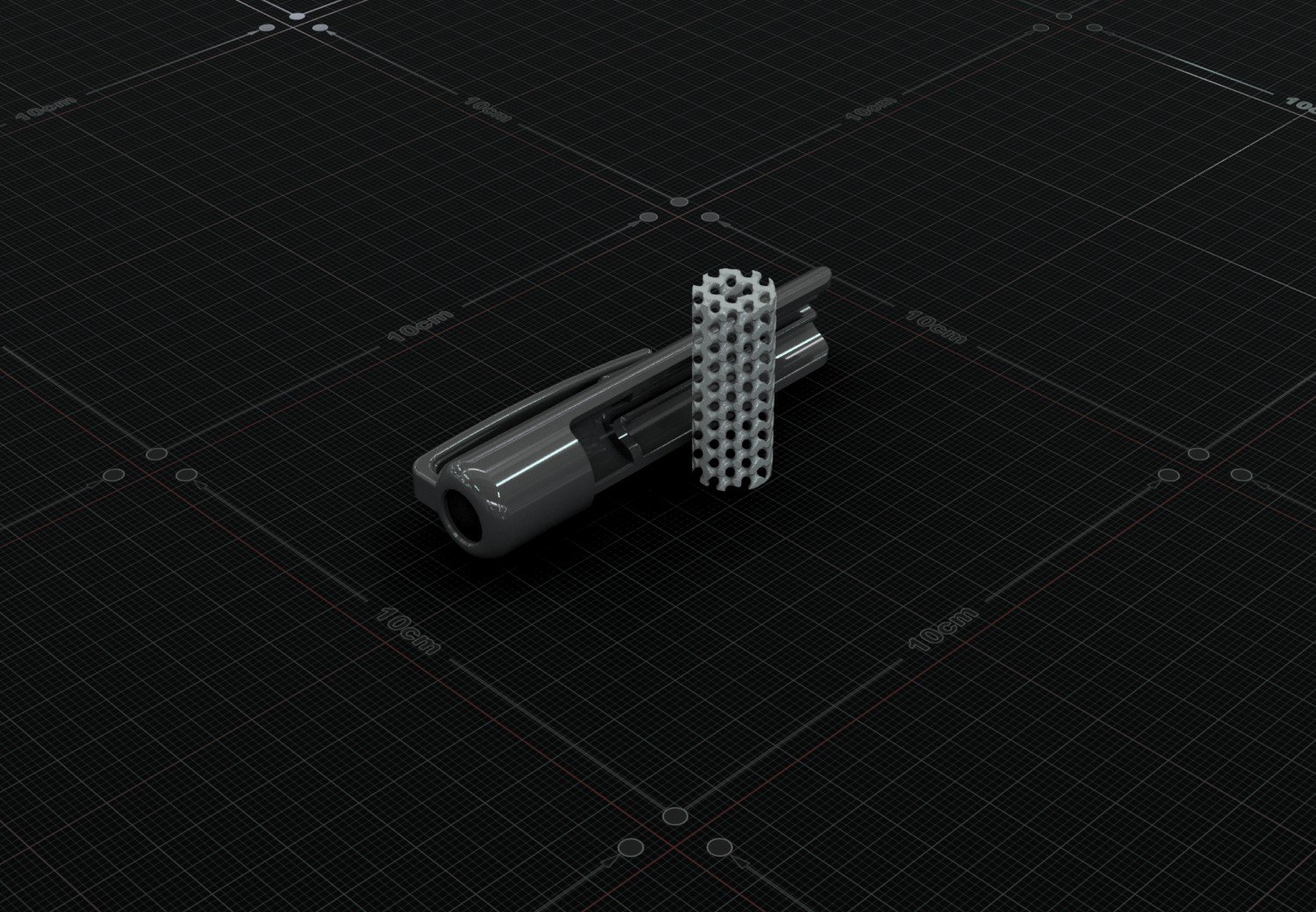

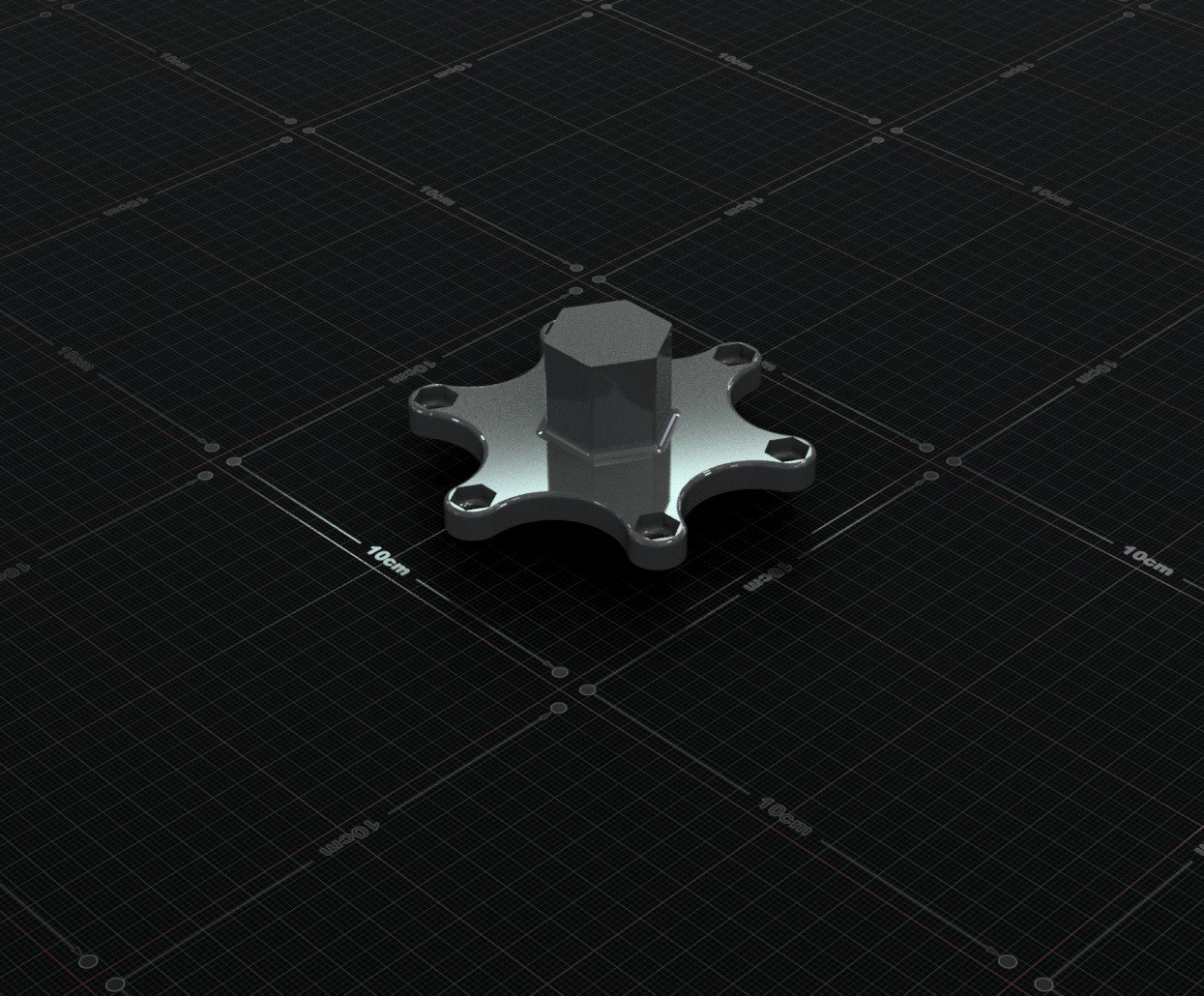

With 3D modeling, you can recreate everyday parts and products, tailoring them to fit your exact needs. For example, this camera part was designed with PPP Cameras, transforming a simple, outdated component into a sleek, polished bronze version. This allows you to customize both the functionality and appearance of the items you use regularly.

Before

Now, you can customize anything to your exact needs, and if you grow tired of the brass, you can easily switch to another material. The great thing about 3D printing is that it allows you to create one-off samples for testing the market. Once you're satisfied with your prototype, you can begin batch production without incurring high startup costs.

After

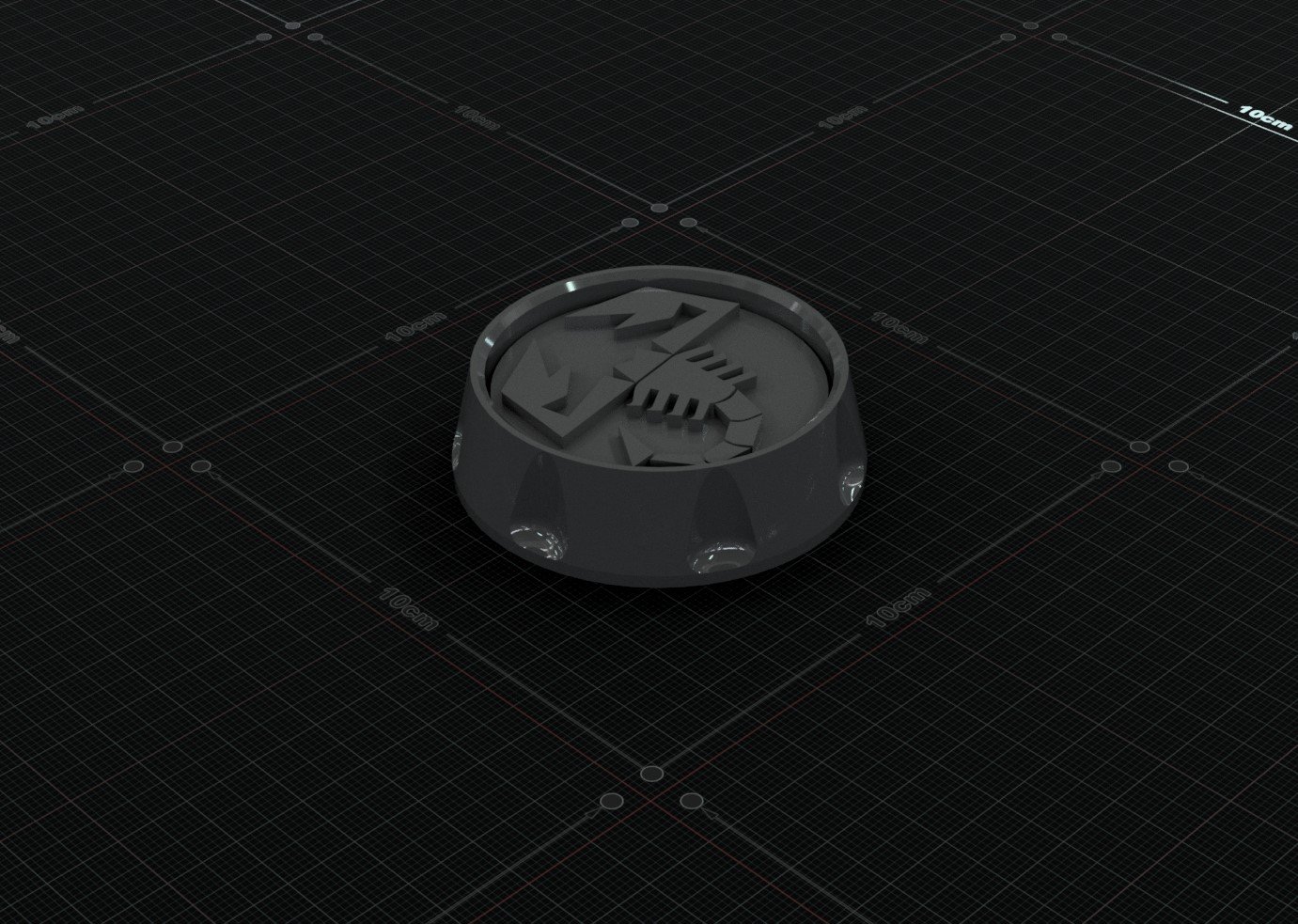

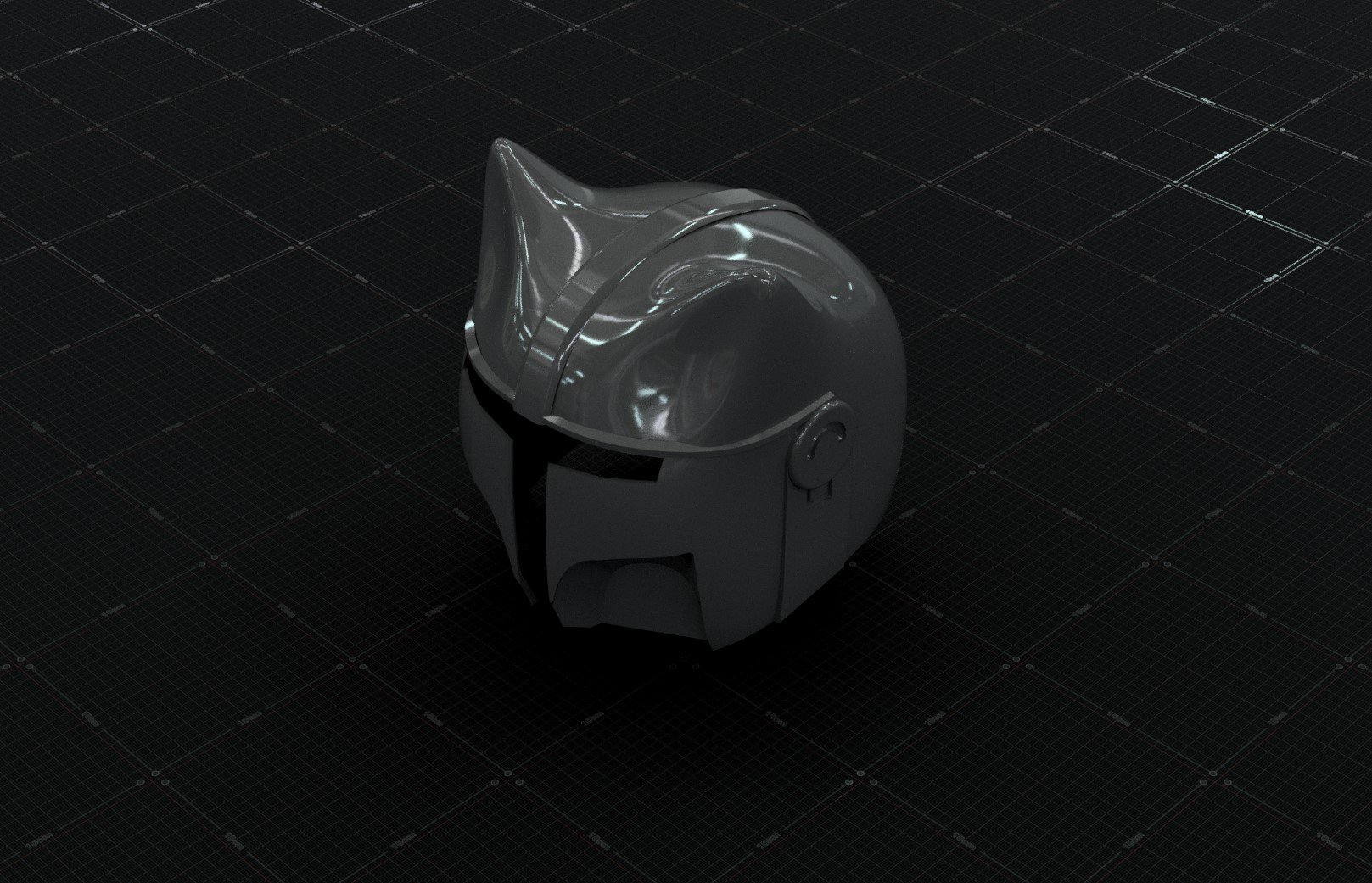

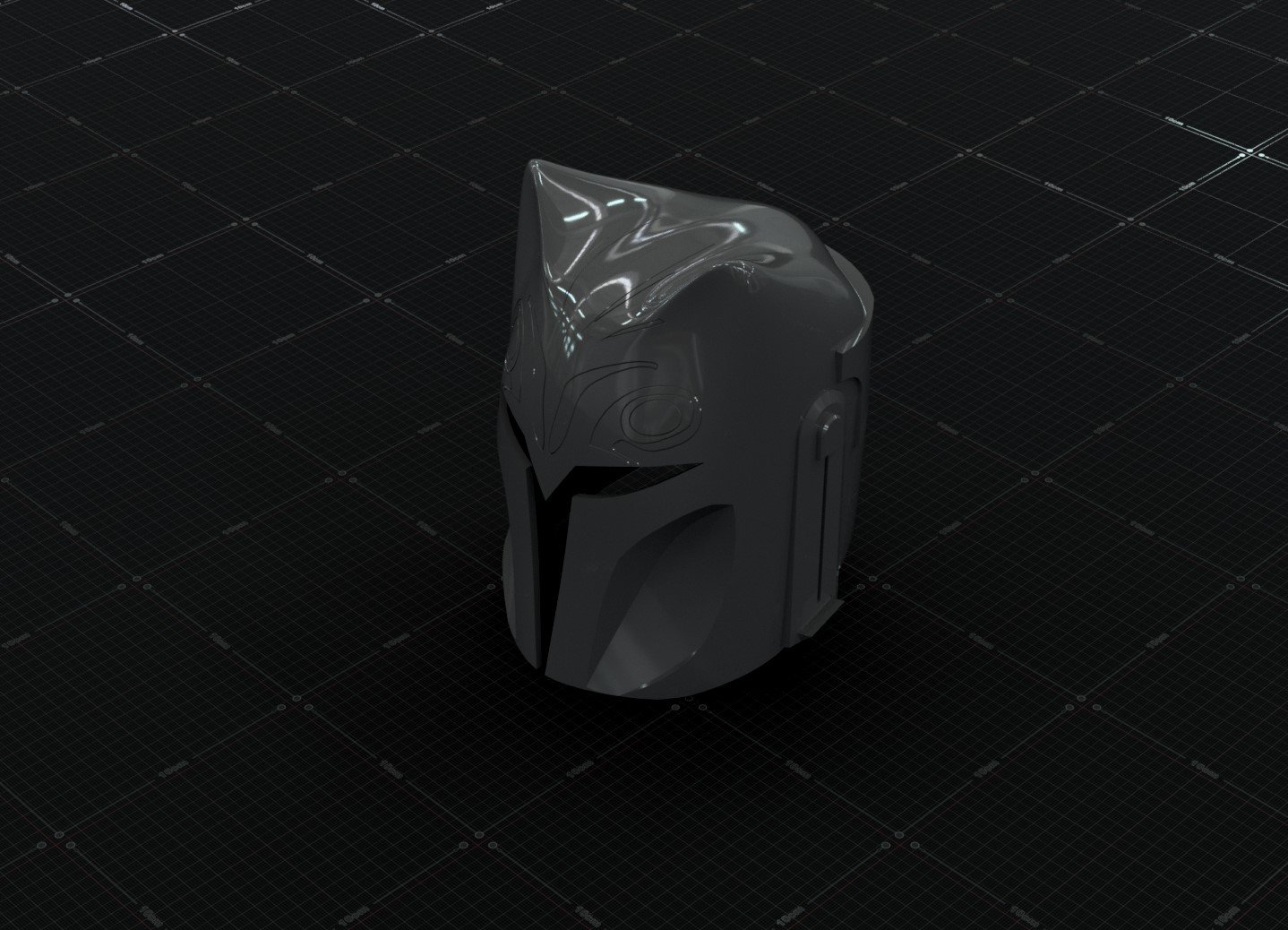

RE-inventing

With 3D modeling, we have helped our clients bring products to market faster and more affordably, streamlining the entire design and production process. At Micro Manufacturing, we specialize in providing tailored solutions that meet the unique needs of our clients. A prime example of this is our collaboration with PPP Cameras, where we worked together to create one-of-a-kind repair tools for film cameras. By utilizing 3D modeling and printing, we were able to design and produce custom tools that perfectly fit the specific requirements of the project, ensuring high precision and efficiency. This approach not only saved time and reduced costs but also enabled us to deliver a fully customized solution that wouldn’t have been possible with traditional manufacturing methods. Whether it's creating bespoke tools or bringing innovative ideas to life, we’re here to help you accelerate your product development and bring your vision to market with ease.

Another advantage of 3D printing is that it doesn't just limit you to recreating existing products. If you have an innovative idea for a new product, 3D printing makes it incredibly easy to bring that idea to life. Whether you're looking to create a completely new design or experiment with unique concepts, 3D printing allows you to quickly prototype and test your creations. This opens up endless possibilities for innovation, enabling you to refine and improve your product before moving forward with larger-scale production. It's a flexible and efficient way to turn your ideas into reality.

for more infomation

Feel free to reach out to us if you have an idea and aren't sure where to begin. We're here to help guide you through the process.